| Max GPM | 3.4 |

| Max L/Min | 13 |

| Max PSI | 1450 |

| MaxBar | 100 |

| Power KW | 2.2 |

| Plunger Dia mm | 18 |

| Stroke mm | 12 |

| Inlet | 1/2" F |

| Outlet | 3/8" F |

| Max Temp | 50℃/122℉ |

| RPM | 1450 |

| Shaft Size | 24mm |

| Shaft Version | N |

| Shaft Type | Solid |

| Shipping Weight(kg) | 8 |

| Oil Type | SAE 15W/40 |

JPBF-N1310

Pistion Seawater Reverse Osmosis Desalination Pump JPBF-N1310

Plunger Pumps are designed for a wide variety of moderate pressure washing applications.

Application:

Manifold:

316 Stainless steel: Strength and no porosity equals long life. Higher hydrostatic pressures, safety, performance

Checking valve:

Stainless steel poppet valve and spring ,brass valve seat,easy to mantain

Crankcase:

Foundry& oxidation technology,biggish heat sink with good heat dissipation

Plunger:

Solid ceramic plunger

SST limit bolt/long service life

Connecting rod:

Aluminum alloy material

High load intensity,long service life

Seals:

corrosion resistant seals,increased pump performance and seal

Related Products

-

High-pressure Triplex plunger pumps 180bar JPB-N0818

High-pressure Triplex plunger pumps 180bar JPB-N0818 -

200bar Ceramic High Pressure Pump Pistion pump JPB-N1120

200bar Ceramic High Pressure Pump Pistion pump JPB-N1120 -

Protable High Pressure Water Jetting 15lpm Reciproating plunger pump JPC-C1535

Protable High Pressure Water Jetting 15lpm Reciproating plunger pump JPC-C1535 -

100bar High Pressure Triplex Ceramic plunger pump JPC-C2110

100bar High Pressure Triplex Ceramic plunger pump JPC-C2110 -

Brilliant sewer jetting pumps with low pressure and higher pressures JPD-7310

Brilliant sewer jetting pumps with low pressure and higher pressures JPD-7310 -

500bar High Pressure Sandblasting Plunger Pump-JPDH-1250

500bar High Pressure Sandblasting Plunger Pump-JPDH-1250 -

500bar Triplex Plunger water Pump For Shipyard JPDH-2250

500bar Triplex Plunger water Pump For Shipyard JPDH-2250 -

JPDS-2850 Durable high pressure Poultry Evisceration plunger Pump Manufacturers

JPDS-2850 Durable high pressure Poultry Evisceration plunger Pump Manufacturers -

JPDS-1880 Ceramic Plunger Reciprocating Pump Manufacturers

JPDS-1880 Ceramic Plunger Reciprocating Pump Manufacturers -

High Pressure Cleaner Plunger Pump by Motor Engine EJPC-C3010

High Pressure Cleaner Plunger Pump by Motor Engine EJPC-C3010

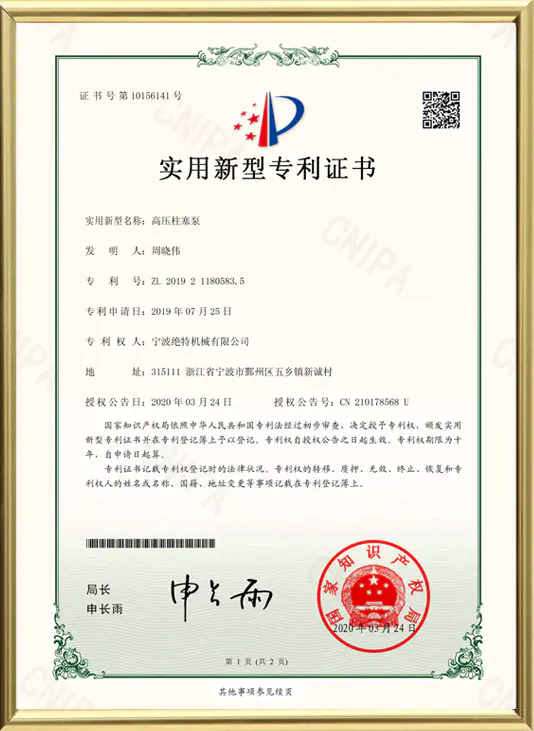

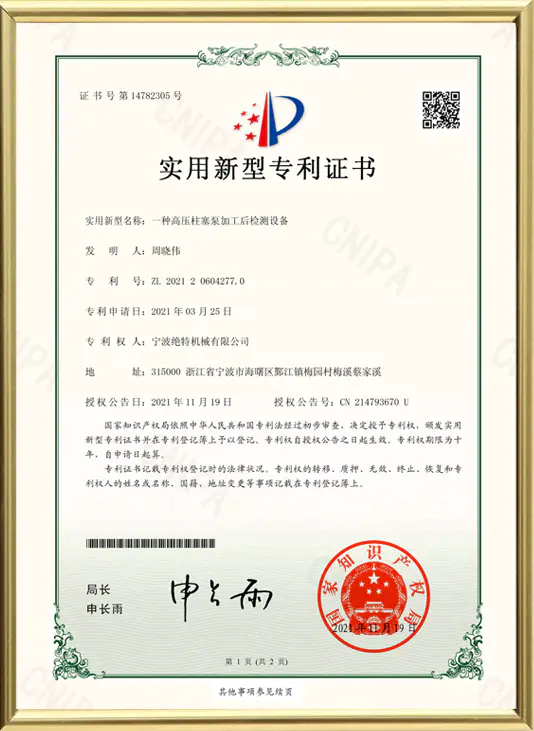

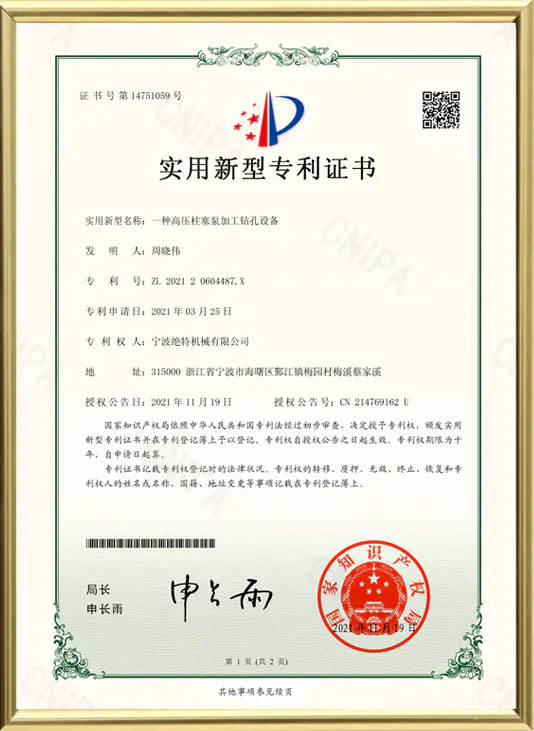

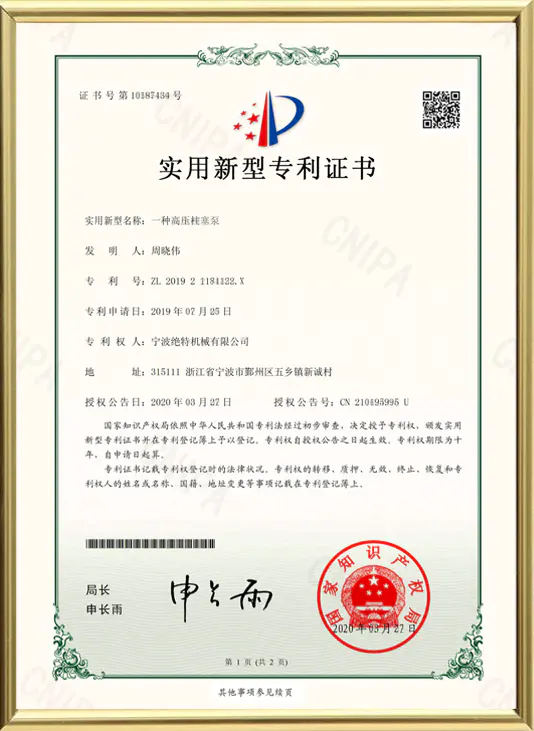

Leading Manufacturer of High Pressure Water Jet Products

Ningbo Brilliant

Ningbo Brilliant Machinery Co., Ltd. was founded in 2019, located in Haishu District, Ningbo. It is a large-scale comprehensive pump company integrating R&D, production and sales of high-pressure plunger pumps. Since its inception, with excellent product quality, accurate market positioning, scientific marketing concept and perfect supporting system, the company successfully set up a quality brand!

The company has more than 3,500 square meters of standard workshops and advanced production processing equipment, including an industrial pump test center and a variety of high precision testing instruments, etc. The company actively introduces high-end German technology and insists on combining product R&D introduction with independent R&D. Its business covers one-stop services such as high-pressure plunger pump production, sales, maintenance, and customization, and is widely used in petroleum, chemical industry, steel, shipbuilding, hydropower, sugar, coal, mining, construction, automobile manufacturing, municipal sanitation, pipeline pressure testing, high-pressure water jet and other fields. At present, the company has carried out strategic cooperation with well-known German industrial pump manufacturers in terms of technical exchanges and product applications. Relying on strong technical strength, high-end production equipment, scientific management methods, and professional quality system, the company has established long-term and stable business relationships with many customers and has won the trust and praise.

The company has a modern office environment and advanced and first-class office facilities. Based on the concept of precise control and customer service, it has quickly gathered a large number of high-quality and high-level talents to join, and has formed a professional R&D, production, operation, sales, maintenance and other core departments. With solid industry theory and experience, the company has focuses on customers, establishes a complete service system, strives to provide customers with the fastest and most efficient products and services, and creates a good brand image.

In the future, we will continue to adhere to the business philosophy of "quality first, reputation first, customer first, service people-oriented", the hard service tenet of "quality control, high efficiency", the leading concept of "fast, efficient, professional and perfect" and the principle of "excellence, stability and development", and take economic benefits as the center. With the support of technological progress, Ningbo Brilliant Water Technology Co., Ltd. will strive to develop into a world-class pump supplier with high technological content, good product quality and excellent personnel quality.

Product Knowledge

Desalination Pump for Coirpump JPBF-N1310, Manifold:316 Stainless steel: Strength and no porosity equals long life. Higher hydrostatic pressures, safety and performance; Check valve:Stainless steel poppet valve and spring ,brass valve seat; Crankcase:Foundry& oxidation technology,big heat sink with good heat dissipation; Plunger:Solid ceramic plunger SST limit bolt/long service lifeUnmatched from the competition, it is ideal for seawater desalination. With a stainless steel build, it is built to last and withstand high-pressure environments. This pump also comes with a solid ceramic plunger that means it will not corrode, enabling long-service life. It is also easy to maintain as it has a brass valve seat that makes maintenance easy and efficient.

This pump is the ideal solution for off-grid solar desalination installations, deep well pumps and other applications where higher pressure is desirable.

This pump is designed to meet the needs of industrial and municipal water treatment, as well as agricultural irrigation, river and lake navigation, pollution control applications

The JPBF-N1310 is a seawater reverse osmosis desalination pump with a stainless steel tank and one-piece casing, including a check valve/ball valve, which makes it ideal for use in environmentally hazardous areas because it can protect against corrosive seawater. Furthermore, its specially designed plunger uses ceramic insulation to prevent heat transfers.

This water pump is suitable for seawater desalination, reverse osmosis (RO) and other similar solution transfer and is also applicable to a variety of other corrosive liquids such as caustic soda, acid or alkali solution, boiler water etc.

A piston desalination pump is a type of submersible pump used for seawater reverse osmosis and brackish water pumping applications. It requires no more than four pumps to push water from the lower part of the pump to the pressure chamber, which is caused by the force applied on each side of the pressure chamber. This is called "towing" suction lift in diving as it resembles a propeller being pulled through water by an engine.

Contact Us

-2(1).png)

English

English Español

Español

.jpg)

.jpg)

.jpg)