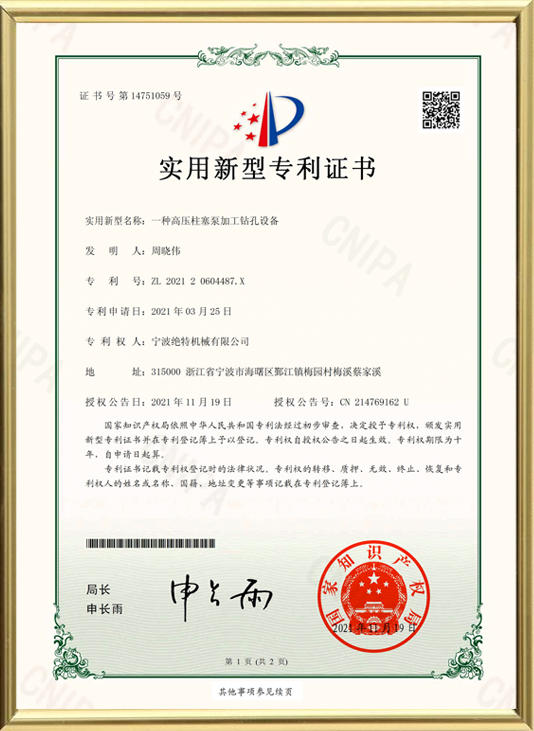

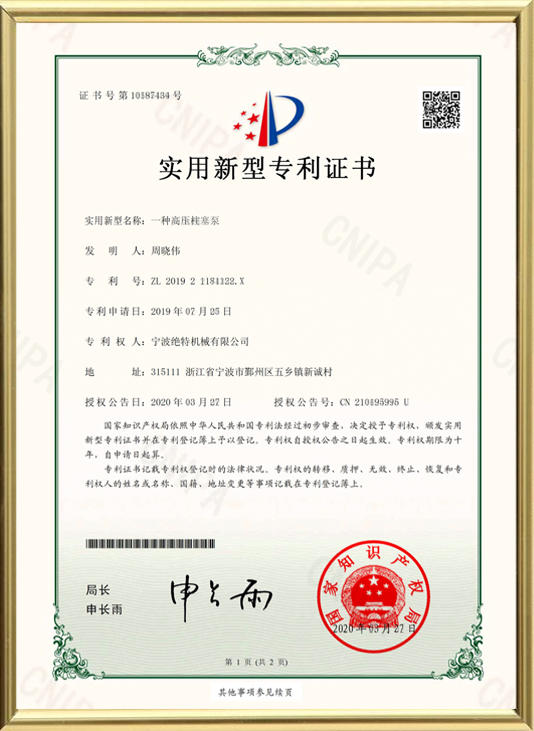

The company has more than 3,500 square meters of standard workshops and advanced production processing equipment, including an industrial pump test center and a variety of high precision testing instruments, etc. The company actively introduces high-end German technology and insists on combining product R&D introduction with independent R&D. Its business covers one-stop services such as high-pressure plunger pump production, sales, maintenance, and customization, and is widely used in petroleum, chemical industry, steel, shipbuilding, hydropower, sugar, coal, mining, construction, automobile manufacturing, municipal sanitation, pipeline pressure testing, high-pressure water jet and other fields. At present, the company has carried out strategic cooperation with well-known German industrial pump manufacturers in terms of technical exchanges and product applications. Relying on strong technical strength, high-end production equipment, scientific management methods, and professional quality system, the company has established long-term and stable business relationships with many customers and has won the trust and praise.

The company has a modern office environment and advanced and first-class office facilities. Based on the concept of precise control and customer service, it has quickly gathered a large number of high-quality and high-level talents to join, and has formed a professional R&D, production, operation, sales, maintenance and other core departments. With solid industry theory and experience, the company has focuses on customers, establishes a complete service system, strives to provide customers with the fastest and most efficient products and services, and creates a good brand image.

In the future, we will continue to adhere to the business philosophy of "quality first, reputation first, customer first, service people-oriented", the hard service tenet of "quality control, high efficiency", the leading concept of "fast, efficient, professional and perfect" and the principle of "excellence, stability and development", and take economic benefits as the center. With the support of technological progress, Ningbo Brilliant Water Technology Co., Ltd. will strive to develop into a world-class pump supplier with high technological content, good product quality and excellent personnel quality.

-2(1).png?imageView2/2/format/jp2)

English

English Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)