Industry knowledge

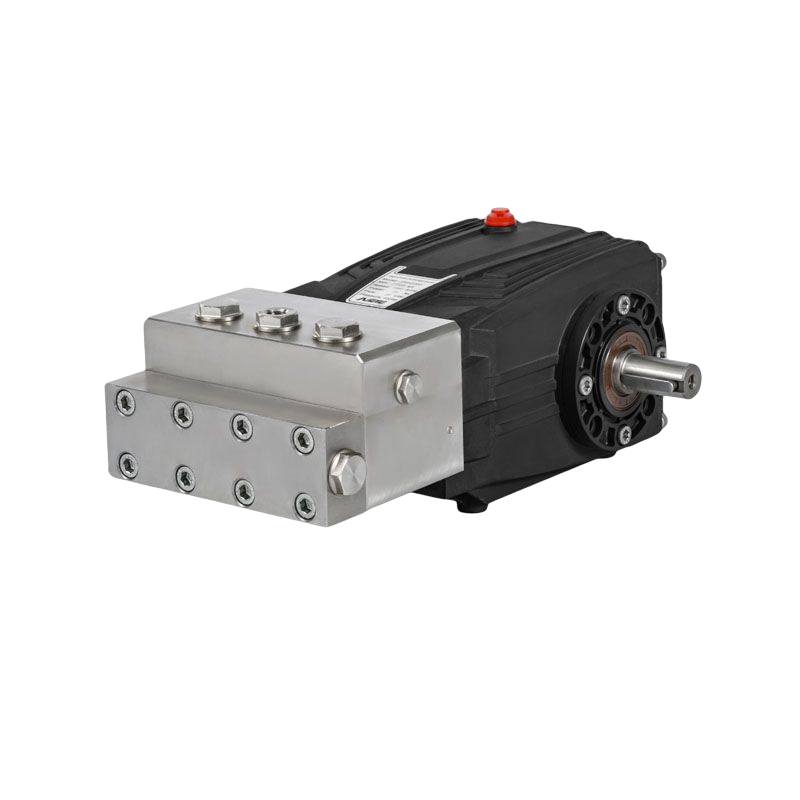

What is High Pressure Plunger Pump Regulate Valves?High pressure plunger pumps are used in a variety of applications, including water treatment, oil and gas production, and manufacturing. One important component of a high pressure plunger pump is the regulate valve.

Regulate valves are used to control the flow of fluid through the pump. They work by adjusting the size of the valve opening, which in turn affects the pressure and flow rate of the fluid. Regulate valves are typically made from durable materials such as stainless steel, and are designed to withstand the high pressures and temperatures associated with high pressure plunger pumps.

There are several different types of regulate valves that can be used with high pressure plunger pumps. One common type is the needle valve, which has a slender, tapered needle that is inserted into a small opening to regulate the flow of fluid. Another type is the ball valve, which uses a spherical ball to control the flow of fluid through the valve.

Regardless of the type of regulate valve used, it is important to ensure that it is properly installed and maintained. Regular inspection and cleaning can help to prevent problems such as clogs or leaks, which can cause damage to the pump and decrease its effectiveness.

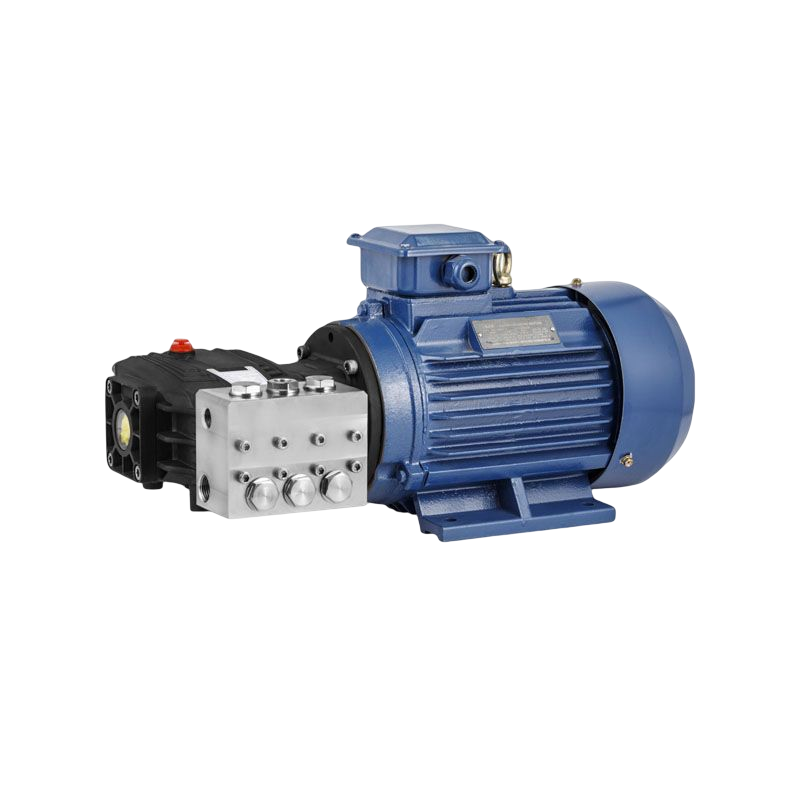

What is product advantages of High Pressure Plunger Pump Regulate Valves?High Pressure Plunger Pump Regulate Valves offer several advantages in various applications where high-pressure liquids need to be controlled. Here are some of the product advantages of High Pressure Plunger Pump Regulate Valves:

Accurate Control: These valves are designed to provide accurate control of high-pressure liquids, which is essential in many industrial applications. The valves allow for precise regulation of the liquid flow rate and pressure, ensuring that the liquid is delivered at the desired rate and pressure.

High Reliability: High Pressure Plunger Pump Regulate Valves are built to withstand the demanding conditions of high-pressure applications. The valves are constructed with high-quality materials, such as stainless steel or brass, and are designed to operate continuously under high pressure and harsh conditions.

Low Maintenance: These valves require minimal maintenance due to their durable construction and high-quality materials. Regular maintenance can help ensure long-term reliability and performance.

Versatility: High Pressure Plunger Pump Regulate Valves can be used in a wide range of applications, such as water treatment, chemical processing, and oil and gas. The valves are suitable for use with a variety of liquids, including corrosive and abrasive fluids.

Cost-Effective: High Pressure Plunger Pump Regulate Valves offer cost-effective solutions for high-pressure liquid control applications. The valves are designed for durability and reliability, which means they have a longer lifespan and require less frequent replacement or maintenance, resulting in cost savings over time.

-2(1).png?imageView2/2/format/jp2)

English

English Español

Español