Industry knowledge

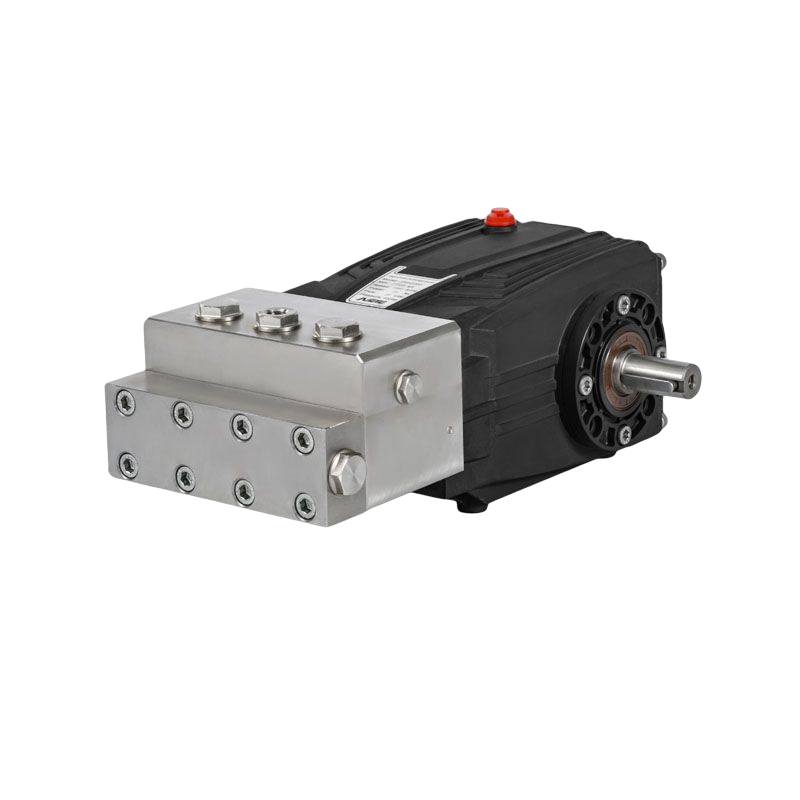

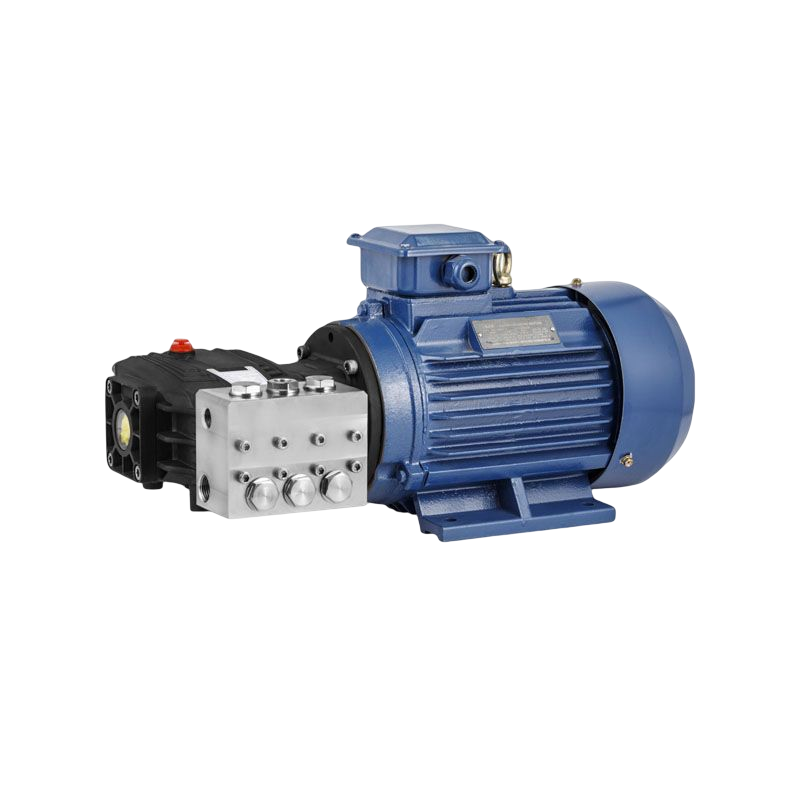

A brief introdction of Industrial high pressure cleaning machineryIndustrial high pressure cleaning machinery is a type of equipment used to clean various surfaces and materials in industrial settings. It typically uses a high-pressure water jet or steam to blast away dirt, grime, grease, and other contaminants from surfaces such as floors, walls, machinery, and vehicles.

These machines are designed to handle tough cleaning jobs in manufacturing plants, construction sites, and other heavy-duty industrial settings where traditional cleaning methods are not sufficient. They come in various sizes and designs to suit different applications, from small handheld units for spot cleaning to large truck-mounted machines for heavy-duty cleaning.

Some common features of industrial high pressure cleaning machinery include adjustable pressure settings, high water flow rates, durable construction, and various nozzle attachments for different cleaning tasks. They can also use a range of cleaning agents and chemicals to help break down stubborn stains and dirt.

Overall, industrial high pressure cleaning machinery is an essential tool for maintaining a clean and safe working environment in various industries.

How to maintain Industrial high pressure cleaning machineryMaintaining

industrial high pressure cleaning machinery is crucial for ensuring optimal performance and longevity of the equipment. Here are some tips to maintain industrial high pressure cleaning machinery:

Read the manual: Always read the manufacturer's manual and follow the maintenance instructions carefully. It will give you the necessary information about the recommended maintenance schedule, how to clean and maintain the machine, and what to do if any issues arise.

Check the water supply: Make sure that the water supply to the machine is clean and free of debris. Dirty water can clog the machine's nozzle and damage the pump. Use a filter or strainer to remove any dirt or debris from the water.

Inspect the hoses: Check the hoses regularly for signs of wear and tear, such as cracks, leaks, or holes. Replace any damaged hoses immediately to prevent further damage to the machine.

Clean the nozzle: The nozzle is a critical component of the high-pressure cleaning machine. It can get clogged with debris or minerals, reducing the machine's efficiency. Clean the nozzle regularly using a wire brush or a nozzle cleaning tool.

Replace worn-out parts: Keep an eye on the machine's parts, including the pump, motor, and other components. Replace any worn-out parts immediately to avoid further damage to the machine.

-2(1).png?imageView2/2/format/jp2)

English

English Español

Español